MicroTek have created a technique to pasteurise opaque liquid food streams at ambient temperatures as a highly energy efficient alternative to thermal pasteurisation or chemical preservation.

The MicroTek system is already being used commercially to pasteurise flavoured sugar syrups with a 95% saving in energy verses previous thermal processes. Plus it has also been used commercially for extending the shelf life of chill chain smoothies and fresh squeezed orange juice.

More recently MicroTek have been working with Reaseheath College to look at the potential benefits of the system within the dairy industry – and recent trials have highlighted ESL of milk and pasteurisation of milk for cheese manufacture to be two areas worthy of further work.

The MicroTek PurePulseTM system installed in Reaseheath Food Centre is available for customer trials outside of the dairy industry too. Other liquid foods such as cider, beer, wine, fruit juices, sugar syrups, sauces and soft drinks can all be trialled. As well as energy saving benefits, there is also reduced infrastructure and capital requirement, as well as reduced operational costs, such as cleaning – which is also good for helping with sustainability strategies.

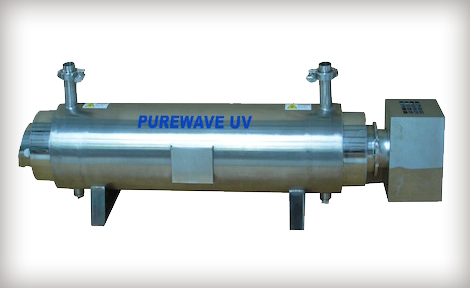

Above are two images from MicroTek’s equipment which form part of their current portfolio:

The MicroTek PureWaveTM MP2 unit is designed for smaller scale pasteurisation sites such as farms, while the MicroTek UVM2 Air steriliser treats 1020m3 of air per hour.